3D Printing Your Models

Introduction to 3D Printing

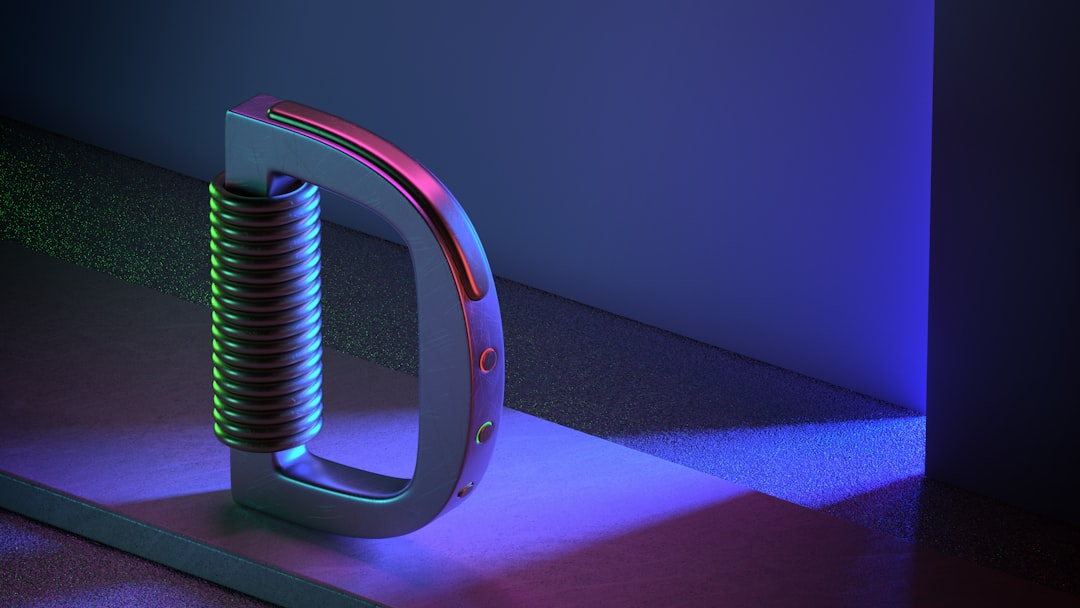

3D printing has revolutionized the way we bring digital designs into the physical world. Whether you're a hobbyist, professional designer, or just curious about the technology, understanding how to prepare your 3D models for printing is essential for achieving successful results.

In this comprehensive guide, we'll cover everything you need to know about taking your 3D models from the screen to physical objects, including file preparation, design considerations, and optimization techniques for different 3D printing technologies.

Understanding 3D Printing Technologies

Before diving into model preparation, it's important to understand the different 3D printing technologies available, as each has its own requirements and limitations:

Fused Deposition Modeling (FDM)

The most common and accessible 3D printing technology:

- Works by extruding melted thermoplastic filament layer by layer

- Affordable and widely available

- Limited resolution compared to other technologies

- Requires support structures for overhangs

- Common materials: PLA, ABS, PETG, TPU

Stereolithography (SLA) and Digital Light Processing (DLP)

Resin-based technologies that offer higher detail:

- Uses light (laser or projector) to cure liquid resin layer by layer

- Higher resolution and smoother surface finish than FDM

- More expensive than FDM

- Requires post-processing (washing and curing)

- Limited build volume compared to FDM

Selective Laser Sintering (SLS)

Powder-based technology used for functional parts:

- Uses laser to sinter powder particles together

- No need for support structures

- Strong, functional parts

- More expensive and primarily used in professional settings

- Common materials: Nylon, TPU, various composites

File Formats for 3D Printing

The standard file formats used in 3D printing include:

STL (STereoLithography)

The most common format for 3D printing:

- Represents the surface geometry of the model using triangular facets

- Simple and widely supported

- Does not store color, material, or texture information

- File size increases with model complexity

OBJ

A more versatile format:

- Can include color and texture information

- Widely supported across modeling and printing software

- Larger file size than STL

3MF (3D Manufacturing Format)

A newer format designed specifically for 3D printing:

- Stores model geometry, material, color, and texture

- More compact than STL

- Includes print settings and other metadata

- Growing support but not as universal as STL

Preparing Your Model for 3D Printing

Checking for Printability

Before sending your model to a printer, ensure it meets these basic requirements:

Watertight Mesh

Your model must be a closed, watertight mesh with no holes or gaps:

- Use software tools like Netfabb, Meshmixer, or your modeling software's built-in check tools

- Fix non-manifold edges, intersecting faces, and reversed normals

- Ensure all parts of the model are connected or separated intentionally

Wall Thickness

Models must have adequate wall thickness to print successfully:

- For FDM printing: Minimum 0.8mm (2-3 times nozzle diameter)

- For SLA/DLP: Minimum 0.5mm

- For SLS: Minimum 0.7mm

- Vary thickness based on structural requirements and material properties

Overhangs and Support Structures

Consider how your model will be printed layer by layer:

- FDM printers typically struggle with overhangs beyond 45 degrees

- Design with printability in mind to minimize supports

- For unavoidable overhangs, ensure your slicing software generates adequate supports

- Consider the orientation of your model to minimize support structures

Optimizing Model Geometry

Polygon Count Optimization

While high-polygon models provide detail, they can cause issues:

- Very high polygon counts can slow down slicing software

- The printer's resolution is the limiting factor, not polygon count

- Use decimation tools to reduce polygons while maintaining important details

- Focus detail where it matters most in the model

Model Orientation

How you orient your model affects print quality and strength:

- Orient to minimize overhangs and support structures

- Consider the layer orientation for structural integrity (parts are typically weaker along the Z-axis)

- Flat surfaces on the build plate typically print better

- Critical features should avoid being supported if possible

Slicing Your Model

Slicing is the process of converting your 3D model into instructions (G-code) that the 3D printer can understand:

Common Slicing Software

- Cura: Free, open-source, works with most FDM printers

- PrusaSlicer: Optimized for Prusa printers but works with others

- Simplify3D: Paid software with advanced features

- Chitubox: Popular for resin printers

Critical Slicing Parameters

Layer Height

Determines the resolution and print time:

- Smaller layer heights (0.1mm) provide better detail but longer print times

- Larger layer heights (0.2-0.3mm) print faster but with visible layers

- Should be selected based on the printer's capabilities and your detail requirements

Infill Percentage and Pattern

Affects strength, weight, and material usage:

- Lower infill (10-20%) for decorative models

- Higher infill (50%+) for functional parts

- Different patterns (grid, honeycomb, gyroid) offer different strength-to-weight ratios

Print Speed

Balances quality and print time:

- Slower speeds generally produce better quality

- Consider different speeds for different features (perimeters, infill, supports)

- Adjust based on your printer's capabilities and material

Material-Specific Considerations

FDM Materials

PLA (Polylactic Acid)

- Easiest to print, biodegradable

- Good for decorative models

- Lower temperature resistance (softens around 60°C)

- Print temperature: 190-220°C

- Bed temperature: 50-60°C or room temperature

ABS (Acrylonitrile Butadiene Styrene)

- More durable and heat-resistant than PLA

- Prone to warping, requires heated bed

- Releases fumes during printing, requires ventilation

- Print temperature: 230-250°C

- Bed temperature: 100-110°C

PETG (Polyethylene Terephthalate Glycol)

- Balance between PLA ease of printing and ABS durability

- Good water resistance

- Less prone to warping than ABS

- Print temperature: 230-250°C

- Bed temperature: 70-80°C

Resin Materials (SLA/DLP)

- Standard resins: Good detail but brittle

- Tough resins: More durable but more expensive

- Flexible resins: For rubber-like parts

- Specialty resins: Castable, dental, biocompatible

Post-Processing Your Prints

FDM Post-Processing

- Support removal: Carefully remove supports with pliers or flush cutters

- Sanding: Start with coarse grit (80-120) and work up to fine (220+)

- Gap filling: Use putty or resin to fill layer lines

- Painting: Use primer first, then acrylic or model paints

Resin Post-Processing

- Washing: Clean uncured resin with isopropyl alcohol

- Curing: Expose to UV light to fully cure

- Support removal: Remove after washing but before final curing

- Sanding: If needed, use fine sandpaper (400+ grit)

Troubleshooting Common 3D Printing Issues

FDM Issues

- Stringing: Adjust retraction settings

- Layer separation: Increase temperature or check for drafts

- Warping: Use a heated bed, apply adhesive, or add a brim

- Under-extrusion: Check for clogs or increase flow rate

Resin Issues

- Failed supports: Increase support thickness or density

- Incomplete parts: Increase exposure time

- Cloudy finish: Ensure proper washing and curing

Conclusion

Successfully 3D printing your models requires understanding the technology, proper model preparation, and appropriate settings for your specific printer and material. While there's a learning curve, the ability to bring your digital creations into the physical world is incredibly rewarding.

Remember that 3D printing is often an iterative process. Don't be discouraged if your first attempts aren't perfect—each print provides valuable feedback that you can use to improve future results. With practice and patience, you'll soon be creating impressive 3D printed models from your digital designs.

In our next article, we'll explore advanced texturing techniques to enhance the visual quality of your 3D models before printing or rendering.